Second-year students, Fatuma Queen, Brian Joel, and three of their school peers, who call themselves the ‘Matrix’, have embarked on an ambitious project to revolutionize poultry farming within their school community. The project showcased their technical skills and underscored the transformative power of project development and management principles acquired through Hatua Network’s eLearning platform.

Their project, the Computerized Egg Incubator, also known as AUTOCIN, garnered significant attention from their school, Masinde Muliro University of Science & Technology. This led them to pioneer the first cohort of MMUST Academy of Innovators- a science and innovation institution launched by the university in March this year.

Under the leadership of their school, Joel, Fatma, and the rest of their team members applied for a patent at the Kenya Industrial Property Institute, catapulting them into the realm of promising young innovators. This blog post explores their journey, highlighting the challenges they identified, the innovative solutions they devised, and the profound impact of their work on the poultry industry and beyond.

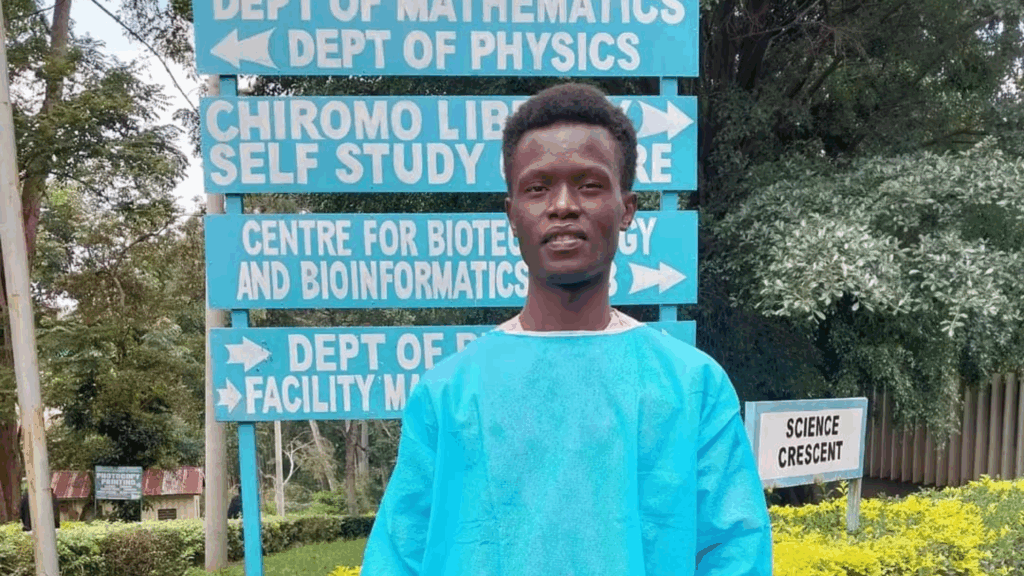

Fatuma Queen and Joel Brian’s Journey

In their second semester of university, Joel and Fatuma enrolled in Hatua’s eLearning Year 1 Volunteer Project course and took on outreach and mentoring projects that focused on vulnerable groups. Through this program, they gained valuable insights on local challenges and learned practical tools to create meaningful solutions. One of the skills they learned was project management, where they trained on project management tools and techniques, such as project mapping using Gantt charts, task prioritization, and the basics of the project life cycle.

The Computerized Egg Incubator

Armed with problem identification and project management skills, they realized that poultry farmers face critical challenges such as poor record-keeping, inefficient incubation processes, and low hatch rates caused by manual errors. Traditional incubators require constant human intervention, lack adaptability for different poultry species, and are prone to hygiene issues, leading to losses.

Their solution? They developed the MATRIX Computerized Egg Incubator, which integrates automation, data tracking, and self-management to improve efficiency, accuracy, and productivity.

The Computerized Egg Incubator has a built-in database that tracks and monitors incubation conditions in real-time and adapts to various poultry eggs, including chicken and duck. The system autonomously controls temperature, humidity, and turning cycles for optimal hatch rates and self-sterilizes using an automatic hygiene system, ensuring a contamination-free incubation environment. It allows farmers to access and control the incubator remotely using digital technology.

Changing the game in agriculture and food security

According to the development team, the computerized egg incubator has the potential to bridge the gap between traditional farming and modern technology. The incubator can increase hatch rates, which lead to increased poultry production, ensuring a stable food supply and enhanced food security. As more people adopt the system, it will encourage entrepreneurship in poultry farming, creating job opportunities.

As the world embraces advanced agricultural technology, Fatuma, Joel, and their peers are pioneering a revolutionary approach to poultry incubation by integrating automation and data for sustainable, scalable farming solutions.

Read More

Read More